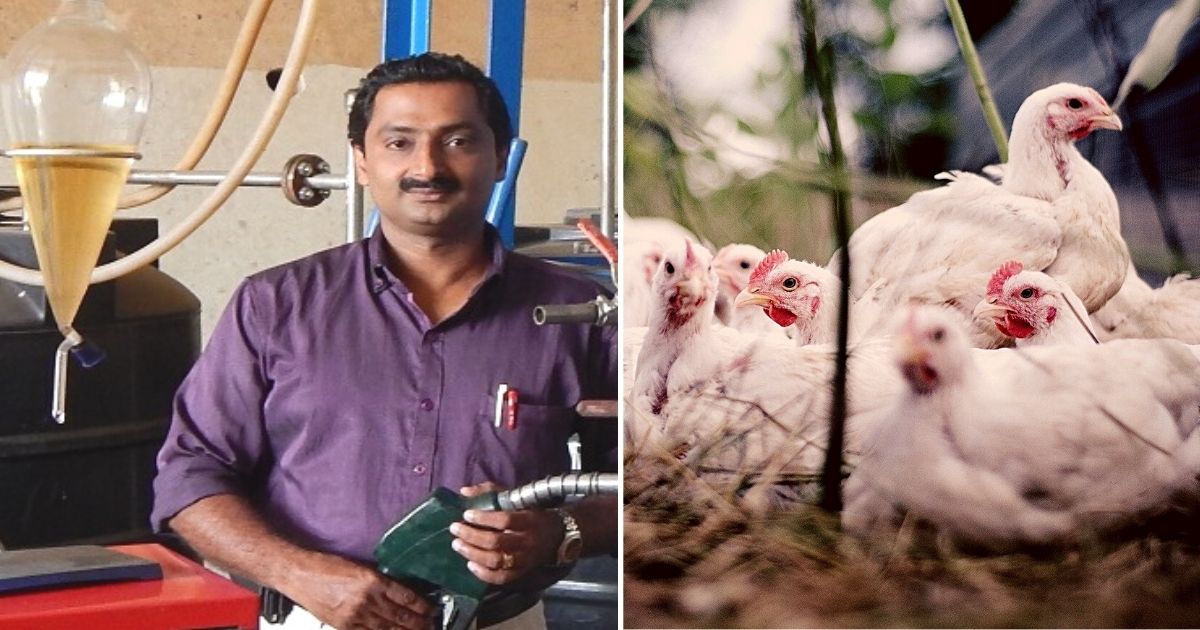

Kerala Vet Invents 40% Cheaper, 50% Less Polluting Biodiesel From Chicken Waste

Writer: Nishit Navin

I have lived in 7 cities across India. I completed my graduation with a triple major in English, Journalism, and animation. Currently, I am doing my master's in journalism from SIMC, Pune.

Kerala, 27 July 2021 4:19 AM GMT

Editor : Palak Agrawal |

Palak a journalism graduate believes in simplifying the complicated and writing about the extraordinary lives of ordinary people. She calls herself a " hodophile" or in layman words- a person who loves to travel.

Creatives : Palak Agrawal

Palak a journalism graduate believes in simplifying the complicated and writing about the extraordinary lives of ordinary people. She calls herself a " hodophile" or in layman words- a person who loves to travel.

During his doctorate research, John Abraham, found the process of producing biodiesel from the waste of slaughtered chicken. The invented fuel offers greater efficiency due to the higher Cetane value compared to conventional diesel.

A veterinarian from Kerala had to wait seven years to receive the patent for his invention. John Abraham invented biodiesel from slaughtered chicken waste that gives an average mileage of 38 km per litre. Offering a cheaper and greener alternative, the fuel reportedly costs 40 per cent less than conventional diesel and causes 50 per cent less pollution.

Delay In Patent Due To Use Of Raw Material Of Fuel

According to NDTV, Abraham had to wait several years for the patent because of the nature of raw material used in the production of the fuel. The patent required permission of the National Biodiversity Authority as the raw material going into the invention was a biological material.

On July 7, Abraham was granted a patent for his "biodiesel produced from rendered chicken oil."

Invention Was Result Of Doctorate Research

Abraham, an associate professor at the veterinary college in Kerala, said that the patent was a result of his doctorate research done at Namakkal Veterinary College under the Tamil Nadu Veterinary & Animal Sciences University.

He conducted his research under the guidance of late Prof Ramesh Saravanakumar, where he discovered the process of creating biodiesel from the waste of slaughtered and dead poultry.

After his successful research, he received funds from the Indian Council for Agricultural Research in 2014 to set up an ₹18 Lakh pilot plant at the Pookode Veterinary College campus in Wayanad. A year later, Bharat Petroleum's Kochi Refinery acknowledged his invention and issued a quality certificate to his biodiesel.

More Efficient, Less Polluting

According to reports, the higher efficiency of his biodiesel is due to the higher content value of Cetane at 72, compared to the 64 per cent present in conventional diesel. Following his lead, three of his students are now working on developing biodiesel from pig waste.

Additionally, it increases engine efficiency by 11 per cent due to the presence of more oxygen and reduces smoke levels by over 47 per cent.

Also Read: Asia's First Sodamaker Brand Utilizes Used Bottles To Reduce Plastic Pollution

All section

All section